- Features & Properties

- Technical Specification

- Gallery

- Related Products

1. It has simple structure and stable operation.

2. The bearings are separated from water and materials to avoid premature damage to the machine caused by contamination and rust.

3. Suitable for a variety of work environments.

4. The loss rate of washed materials is low and the washing efficiency is high, which can fully meet the requirements of high-grade materials.

5. The service life is long and it has almost no wearing parts.

6. Repairs are rarely required, thus significantly reducing costs.

| Model | Spiral diameter (mm) | Tank length (mm) | Speed (rpm) | Capacity (t/h) | Power(kw) | Dimensions (mm) |

| XL915 |

915 |

7685 | 21 | 100 | 11 | 8500×2810×3600 |

| 2XL915 | 200 | 11×2 | 8520×3760×3960 | |||

| XL1115 |

1115 |

9785 | 17 | 150 | 15 | 10780×3980×4170 |

| 2XL1115 | 300 | 15×2 | 10970×5250×4720 | |||

| XL1250 |

1250 |

9790 | 17 | 180 | 18.5 | 10950×4130×4590 |

| 2XL1250 | 360 | 18.5×2 | 11150×5400×5140 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

PXJ Fine hammer crusher

PXJ Fine hammer crusher

PL Composite vertical shaft crusher

PL Composite vertical shaft crusher

WS Waterwheel sand washer

WS Waterwheel sand washer

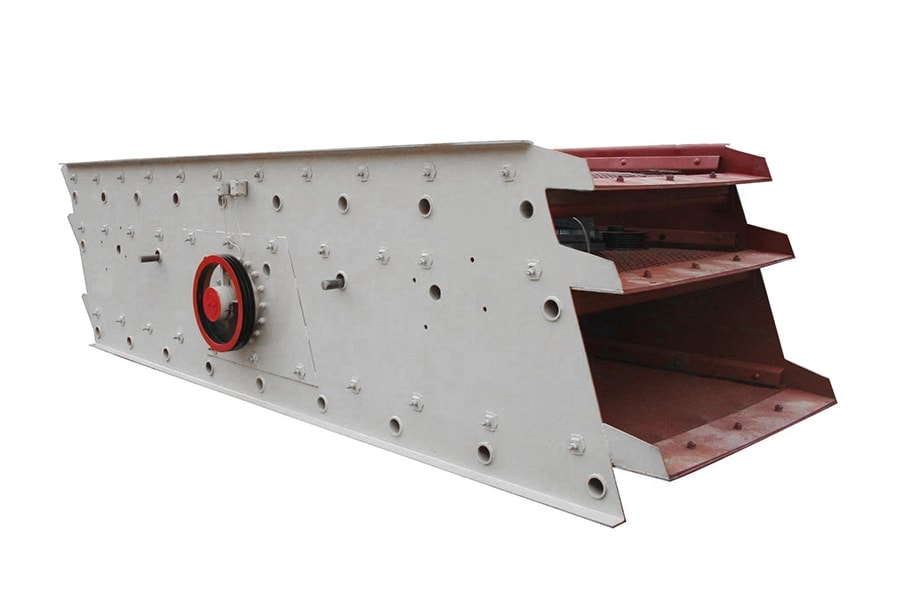

YK Vibrating screen

YK Vibrating screen

FAQ

Q: What are the application scope and characteristics of spiral sand washer?

A: The spiral sand washer is used for desliming and screening at construction sites, aggregate plants, prefabricated plants and water and electricity construction sites, and can also be used for ore separation. It can effectively handle materials within 0-30mm, and can wash away the soil and dust on the materials to obtain clean materials. The spiral sand washer has the advantages of simple structure, easy maintenance and high efficiency.

Spiral sand washer is divided into double spiral sand washer and single spiral sand washer . Double spiral sand washer is more efficient and has greater capacity than single spiral sand washer. The rotor of the double-spiral sand washer adopts a central structure, the spiral blades are installed on the central shaft, and a reducer is connected to the central shaft for work. It performs mechanical classification based on the principle that solid particles have different settling speeds in liquids due to different specific gravity.

Q: What is the difference between the sand washing effect of waterwheel sand washer and spiral sand washer? How to choose a suitable sand washer?

A: Waterwheel sand washer and spiral sand washer are both equipment used for sand washing and impurity removal. Although their appearance and working principle are different, because the work content is the same, people are used to comparing the two together. Some users often struggle with which one is better when purchasing, so let’s compare them.

1) Washing principle. When the waterwheel sand washer is working, the motor provides power to the waterwheel to rotate, and the reducer decelerates the waterwheel so that the waterwheel rotates slowly. The sand first enter the tank and are driven by the waterwheel to tumble. At this time, water comes in and can take away the impurities. The qualified sand is discharged from the overflow opening of the washing tank. Spiral sand washers are generally placed at an angle. The spiral blades drive the sand upwards, and the water pipes supply water. The washed fine sand and soil flow to the sedimentation tank below with the water flow, and the clean sand is discharged from the discharge port above.

2) Appearance and structure. The waterwheel sand washer has a short and wide structure, simple structure and small footprint. The spiral sand washer has a long and thin horizontal structure. It requires a certain tilt angle during installation. After the position is determined, a professional bracket needs to be welded. It is not as simple and convenient as the waterwheel sand washer.

3) Washing cleanliness. Under the same circumstances, the spiral sand washer can wash the same materials more cleanly than the waterwheel sand washer. From the working principle, the spiral sand washer pushes the sand forward through the spiral blades. There will be a friction between the sand, the blades and the tank, which is similar to washing clothes. Therefore, it will wash cleaner, especially when the material contains mud.

4) Water consumption. The waterwheel sand washer requires a large amount of water to remove impurities. For the same material, it requires more water than the spiral sand washer.

5) Tailings loss. When using a spiral sand washer to wash sand, the sand goes up and the water flows down with impurities. In this process, the fine sand will also be brought out with the water flow. Therefore, the tailings loss of the spiral sand washer is large, and the product gradation is very affected. Therefore, under normal circumstances, manufacturers will recommend equipping a fine sand recovery machine with the spiral sand washer.

6) Purchase price. Comparing the two machines, the waterwheel sand washer has a simpler structure than the spiral sand washer and the purchase cost is lower. Moreover, its bearings have no contact with water or materials, are not prone to rust, have few wearing parts, and have low maintenance costs. In addition, it does not need to be equipped with a fine sand recovery machine, thus saving another budget.

In general, the waterwheel sand washer occupies a small area and has low initial investment pressure. Bosses who do not have sufficient budget should choose the waterwheel sand washer. But if your sand contains more than 30% mud and you want to save water, it is better to choose a spiral sand washer.