- Features & Properties

- Technical Specification

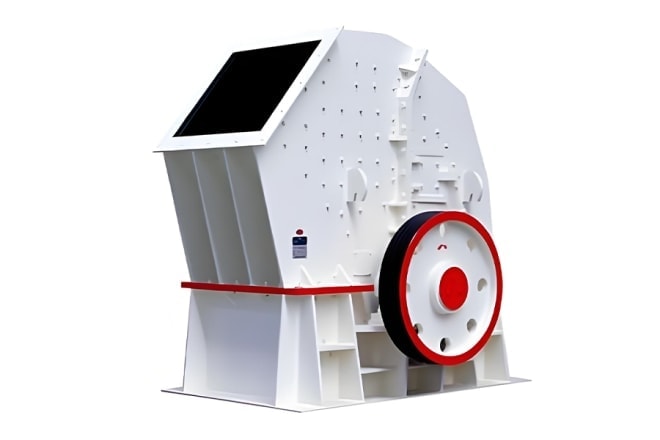

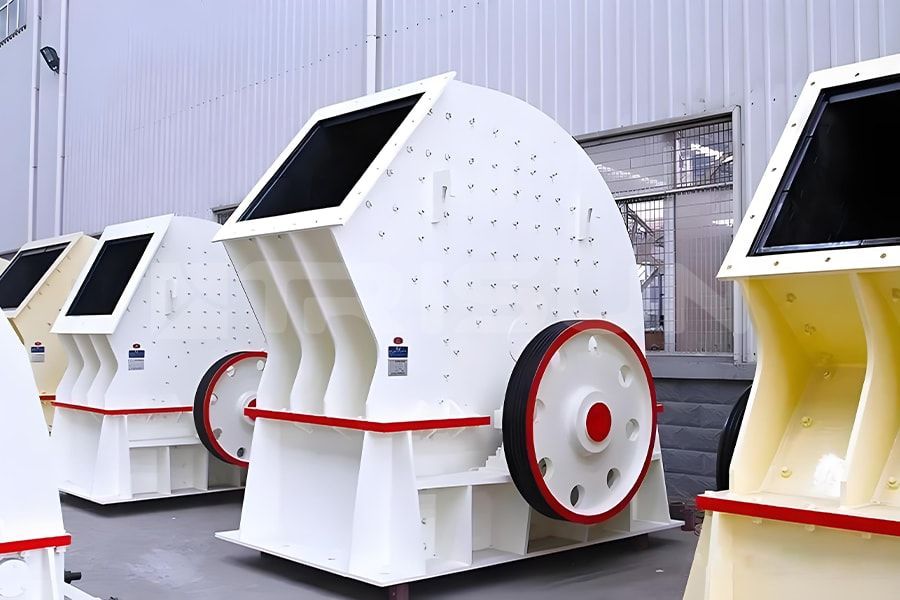

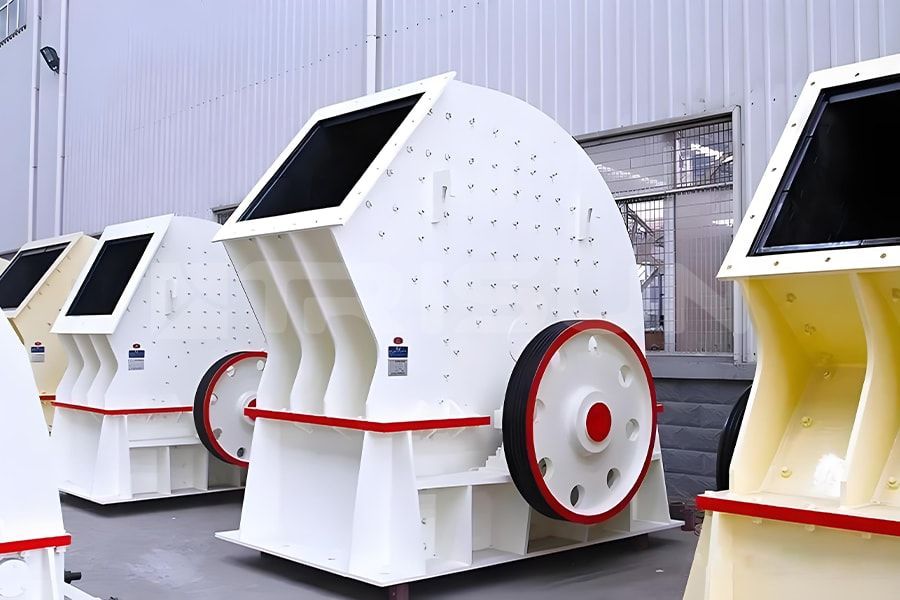

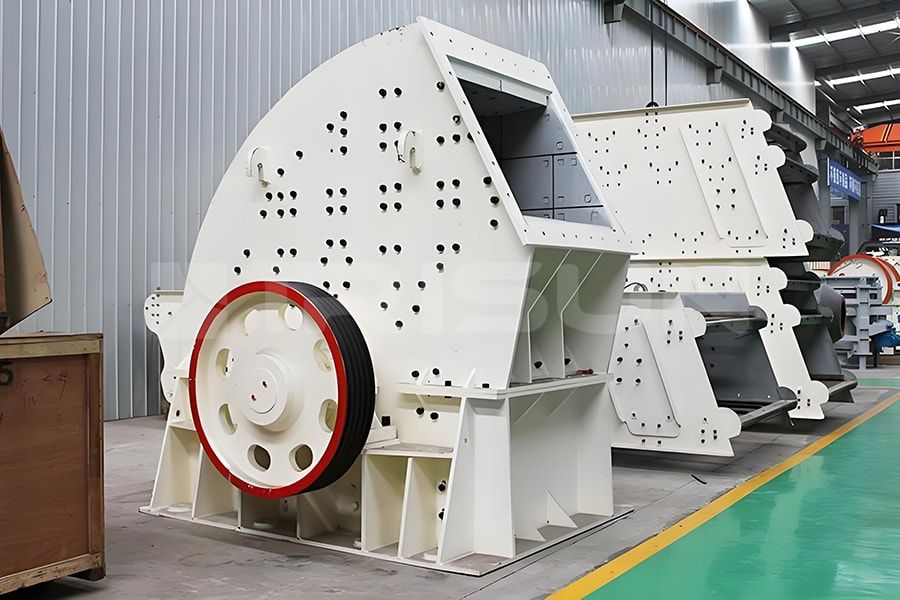

- Gallery

- Related Products

1. It is allowed to feed materials with large size (up to 1200mm), large crushing ratio, and small discharge size (up to 3mm).

2. The operation cost is low, the system supporting power is small, the production cost is greatly reduced, and the energy saving is more than 40% compared with the conventional three-stage crusher.

3. It is suitable for single-stage fine crushing of medium hardness and brittle materials, and can replace the traditional three-stage crushing system.

4. Widely used in cement, ceramics, glass, artificial aggregate, coal, non-metal mining and new green building materials industries.

| Model | Rotor specifications (mm) | Feed opening size (mm) | Maximum feeding size (mm) | Capacity (t/h) | Power(kw) | Dimensions (mm) |

| PCZ1310 | Ф1310×1000 | 850×1000 | 600 | 120-200 | 132 | 2818×2100×2390 |

| PCZ1312 | Ф1310×1200 | 850×1200 | 600 | 150-240 | 112×2 | 2818×2300×2390 |

| PCZ1510 | Ф1500×1000 | 900×1000 | 700 | 160-280 | 132×2 | 3260×2414×2750 |

| PCZ1512 | Ф1500×1160 | 900×1200 | 750 | 250-320 | 160×2 | 3260×2624×2750 |

| PCZ1615 | Ф1650×1452 | 1200×1500 | 1000 | 420-500 | 200×2 | 3456×2915×3185 |

| PCZ1620 | Ф1660×1900 | 1200×2000 | 1000 | 800-1000 | 315×2 | 3500×3100×3200 |

| PCZ1820 | Ф1800×1964 | 1200×2000 | 1200 | 1000-1200 | 450×2 | 3270×3210×3520 |

| PCZ1822 | Ф1800×2180 | 1200×2100 | 1200 | 1200-1600 | 500×2 | 3280×3416×3528 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

FAQ

Q: Why is heavy hammer crusher also called a two-in-one or three-in-one crusher? What are the advantages?

A: The heavy hammer crusher has a large input size and a small output size, changing the three-stage crushing into one-stage crushing, completely realizing the low operating cost of one crusher replacing multiple crushers. It can reduce costs by about 35% and is a device with low energy consumption and low investment. The heavy hammer crusher is a new generation crusher developed after optimized design based on the ordinary hammer crusher, impact crusher, vertical shaft hammer crusher and other machines that use hammers to crush stone. It changes the method of using grate bars to control the size of discharged particles, reduces the wear of the hammer in the crushing cavity, and increases the life of the hammer by 4-6 times. Not only that, it can also crush wet materials, which means that water can be added when crushing wet materials to reduce dust pollution and protect the environment and worker health.

Q: What is the difference between heavy hammer crusher and ordinary hammer crusher?

A: 1) The feed opening of heavy hammer crusher is larger than that of ordinary hammer crusher. It is generally used for coarse crushing, that is, the primary crushing. In projects, especially large-scale crushing plants, ordinary hammer crushers are often used with heavy hammer crushers for medium or fine crushing.

2) The hammer in the heavy hammer crusher is heavier than the hammer of the ordinary hammer crusher, generally higher than 20kg, so the crushing force of the material is greater, and the material that can be crushed per unit time is significantly higher than that of the ordinary hammer crusher.

Q: What are the precautions for using heavy hammer crusher?

A: Careful inspection should be carried out before installation, problems caused during transportation should be discovered and eliminated in time, and installation should be carried out according to the following requirements:

1) The heavy hammer crusher should be installed on the concrete foundation.

2) In order to prevent the vibration generated by the heavy hammer crusher from affecting the building when working, hard boards or other shock-absorbing materials should be placed between the heavy hammer crusher and the concrete foundation.

3) When installing the heavy hammer crusher, the centers of the motor and rotor shafts should be kept straight to avoid premature damage to the elastic sleeve on the coupling and heating of the bearings.

Q: What are the installation requirements for heavy hammer crusher?

A: 1) Heavy hammer crushers require a good grounding connection to ensure safe use.

2) The equipment needs to be inspected and maintained before use to ensure that all components are in good condition.

3) During use, the equipment needs to be lubricated regularly to maintain lubrication.

4) When using a heavy hammer crusher, you need to wear protective equipment, such as safety helmets, masks, etc., to avoid accidental injuries.

5) When the heavy hammer crusher is not in use, its power supply should be cut off to avoid wasting power or causing unnecessary danger.