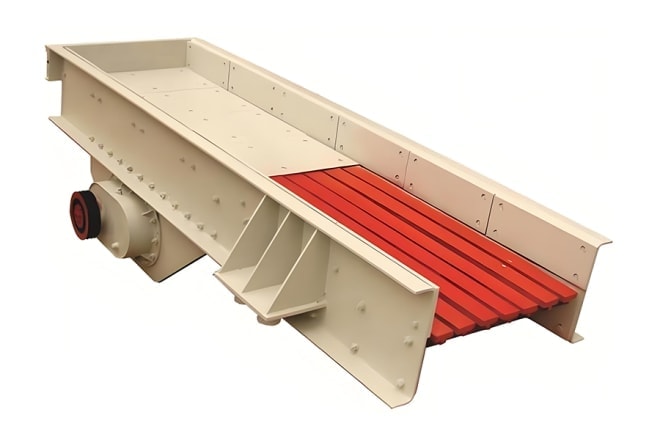

- Features & Properties

- Technical Specification

- Gallery

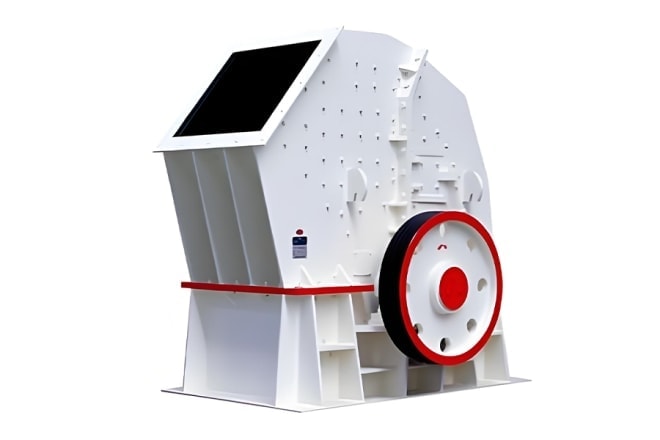

- Related Products

1. Simple structure, easy installation, stable vibration, reliable operation, long life, easy maintenance and inspection, and easy automatic control.

2. It uses a biaxial vibrator, vibrates in a straight line and completes screening while feeding, which improves the utilization rate and reduces costs;

3. It can continuously and evenly feed the primary crusher and pre-screen the materials at the same time;

4. It can optionally be equipped with a variable frequency motor, making it easy to control the feeding amount without starting the motor frequently.

| Model | Feed trough size(mm) | Maximum feeding size (mm) | Capacity (t/h) | Power(kw) | Dimensions (mm) | Weight (t) |

| ZSW9638 | 3800*960 | 600 | 100-180 | 11 | 3850*1950*1630 | 4.2 |

| ZSW9642 | 4200*960 | 700 | 120-220 | 11 | 4255*1950*1660 | 4.4 |

| ZSW1142 | 4200*1100 | 700 | 180-320 | 15 | 4400*2050*1660 | 4.8 |

| ZSW1149 | 4900*1100 | 800 | 220-400 | 15-18.5 | 5200*2050*1700 | 5.6 |

| ZSW1349 | 4900*1300 | 800 | 320-550 | 22 | 5200*2350*1750 | 6.7 |

| ZSW1360 | 6000*1300 | 800 | 400-600 | 22 | 6082*2400*2083 | 7.8 |

| ZSW1560 | 6000*1500 | 1000 | 500-800 | 30-37 | 6086*2270*2190 | 9.0 |

| ZSW1860 | 6000*1800 | 1000 | 700-1000 | 37-45 | 6310*2570*2350 | 10.8 |

| ZSW2060 | 6000*2000 | 1000 | 800-1200 | 45-55 | 6310*2780*2450 | 11.9 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

FAQ

Q: What are the usage conditions of vibrating feeder?

A: 1) The ambient temperature does not exceed +40℃;

2) When the ambient temperature is 20±5℃, the relative humidity of the surrounding medium is not greater than 85%;

3) There is no serious corrosion or medium that affects electrical insulation around it.

Q: How many types of mining feeders are there? How to choose?

A: At present, commonly used mining equipment mainly includes belt feeders, trough feeders, disc feeders, swing feeders, vibrating feeders, electromagnetic vibrating feeders and plate feeders. When choosing a suitable feeder, you need to consider many aspects such as the size, density, humidity, and viscosity of the material, the feeding capacity and the installation location of the feeder.

Q: What are the operation and maintenance procedures for vibrating feeders?

A: 1) Preparations before starting:

1-1. Read the duty records and deal with the problems left over from the previous shift.

1-2. Check and remove debris that may affect the movement of the vibrating feeder.

1-3. Carefully check that all fasteners are fully tightened.

1-4. Check whether the lubricating oil in the exciter is higher than the oil level.

1-5. Check whether the transmission belt is in good condition. If it is damaged, replace it. If there is oil stain, wipe it with a rag.

1-6. Check whether the protective devices are in good condition and eliminate them promptly if any unsafe factors are found.

2) Starting and using:

2-1. After inspection, if the machine and transmission parts are in normal condition, it can be started.

2-2. The machine is only allowed to be started without load.

2-3. After starting, if any abnormality is found, it should be stopped immediately. It can only be started again after the abnormality has been identified and eliminated.

2-4. After the machine has stabilized its vibration, it can be operated under load.

2-5. Feeding should meet the load test requirements.

2-6. The shutdown should be carried out in the same direction as the process. It is forbidden to stop the machine with materials or continue to feed materials during or after shutdown.

Q: What are the safety regulations for the installation and testing of vibrating feeders?

A: 1) If the vibrating feeder is used for batching or quantitative feeding, it should be installed horizontally to ensure uniform and stable feeding and prevent the material from flowing. If it is used for continuous feeding of general materials, it can be installed with a downward angle of 10°. For viscous materials and materials with a large moisture content, it can be installed at a downward angle of 15°.

2) The vibrating feeder after installation should have a 20mm gap, the transverse direction should be horizontal.

3) Before no-load test, all bolts should be tightened once. After continuous operation for 3-5 hours, they should be tightened again.

4) During operation, the stability of amplitude, current and noise should be checked frequently, and if any abnormalities are found, the machine should be stopped in time.

5) Bearings should be filled with lubricating oil every 2 months, and once a month during high temperature seasons.