- Features & Properties

- Technical Specification

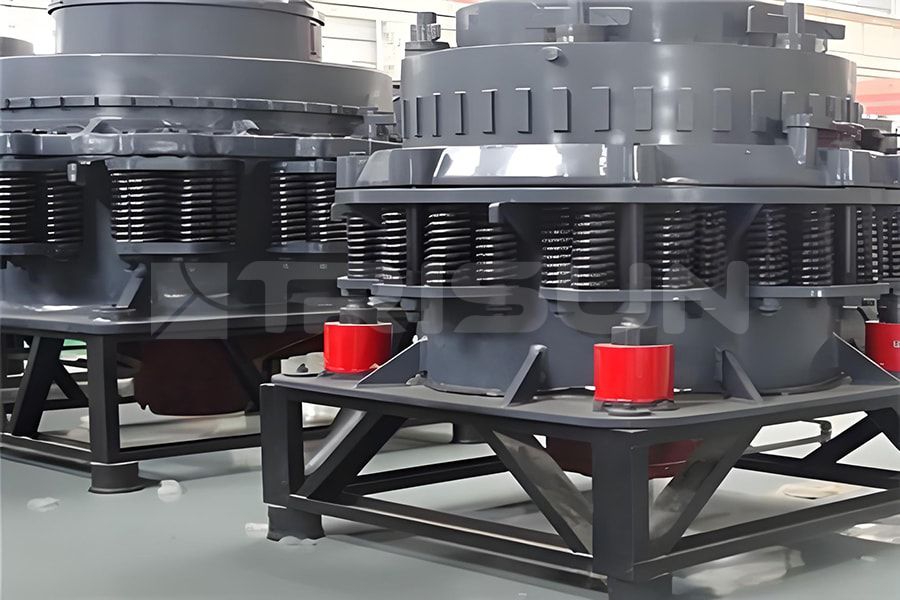

- Gallery

- Related Products

1. Higher productivity, better quality.

2. Due to the safety device, it significantly reduces downtime.

3. The casing is made of cast steel, with reinforcement ribs in heavy-load areas.

4. Equipped with an adjuster, discharging sizes can be quickly adjusted.

5. Equipped with spring-loaded protection device.

6. It has a complete lubrication system that will automatically shut down when the oil temperature is too high or the oil flow rate is too slow.

7. The internal structure has good sealing performance and can effectively protect the crusher from dust and other small particles.

8. Long service life and strong applicability.

| Mantle diameter | Model | Maximum feeding size (mm) | Discharge opening range (mm) | Capacity (t/h) | Power(kw) | Weight (t) | Dimensions (mm) |

| 2’ | PYB600 | 65 | 12-25 | 12-25 | 30 | 5 | 2800×1300×1700 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | |||

| 3’ | PYB900 | 115 | 15-50 | 50-90 | 55 | 11.2 | 3050×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | |||

| 4’ | PYB1200 | 145 | 20-50 | 110-168 | 110 | 24.7 | 4152×2300×2980 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | |||

| 5 ½’ | PYB1750 | 215 | 25-50 | 280-480 | 160 | 50.2 | 4870×3800×4192 |

| PYZ1750 | 185 | 10-30 | 115-320 | 50.3 | |||

| PYD1750 | 85 | 5-13 | 75-230 | 50.3 | |||

| 7’ | PYB2200 | 300 | 30-60 | 59-1000 | 240-280 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 200-580 | 80 | |||

| PYD2200 | 100 | 5-15 | 120-340 | 81.4 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

FAQ

Q: What is the difference between cone crusher and gyratory crusher?

A: 1) Shape of crushing cavity. The two cones of the gyratory crusher are steeply inclined, the movable cone (mantle) is an upright cone, and the fixed cone (concave) is an inverted cone. This is mainly to increase the feed opening. The two cones of the cone crusher are both gently inclined and upright cones. There is a certain length of parallel crushing zone between the two cones, which is to control the discharging size.

2) Hanging method of mantle. The moving cone of the gyratory crusher is suspended on the beam of the frame; the moving cone of the cone crusher is supported by spherical bearings.

3) Dust removal device. The gyratory crusher adopts a dry dust-proof device; the cone crusher adopts a water-sealed dust-proof device.

4) Adjustment method of discharge opening. The gyratory crusher adjusts the size of the discharge opening by raising or lowering the movable cone, while the cone crusher adjusts the size of the discharge opening by adjusting the height of the fixed cone.

Q: What are the advantages and disadvantages of PY spring cone crusher?

A: Advantages: Long manufacturing history and high market share.

Disadvantages: Former Soviet Union technology is bulky, large in size, and has high installation, overhaul and maintenance costs; It does not have the functions of hydraulic cavity cleaning and hydraulic adjustment of the discharge opening. When cleaning the cavity or adjusting the discharge opening, it is time-consuming, laborious and delays normal production; Replacing the concave and mantle requires filling with epoxy resin and other fillers, which is costly and troublesome. For cold, high-humidity seasons or areas, it takes a long time to dry after filling, seriously affecting normal production.

Q: How to use spring cone crusher reasonably?

A: 1) The discharge opening needs to be adjusted according to the wear degree of the concave and mantle to ensure the discharge granularity.

2) Due to the machining error on the surface of the concave and mantle, in order to ensure the safe operation of the equipment, it is necessary to avoid collision between them.

3) The spring cone crusher must not be overloaded. For example, the feeding size are too large, the discharge opening is too small, and the feed opening is enlarged at will.

4) The maximum feed size should be 80-85% of the feed opening.

5) When unbreakable materials (iron, metal, etc.) enter the cavity, the spring plays a role in protecting the cone crusher.

Q: What items need to be checked when the cone crusher is running?

A: 1) It should be closely observed whether the lubricating oil pressure is normal (around 400Kpa), and whether the oil tank and return oil temperatures are normal;

2) Check the oil return filter of the lubrication station every 10-15 minutes to see if there are any copper or aluminum sheets;

3) Whether the air cooler starts when the return oil temperature exceeds 45°C; whether the air cooler stops running when the return oil temperature is lower than 39°C;

4) When the current exceeds 450A, whether there is an audible and visual alarm;

5) Whether the accumulator pressure is normal;

6) Whether the PLC is working normally;

7) Whether the pressure of the hydraulic system is normal; whether the adjustment ring beats normally;

8) Is the feed supply normal (the distribution needs to be even to achieve sufficient feeding).