- Features & Properties

- Technical Specification

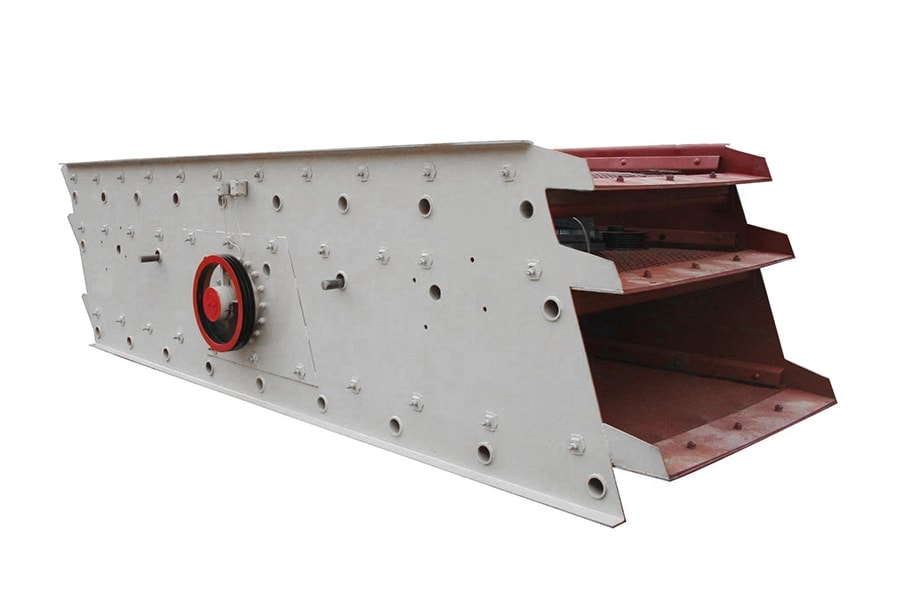

- Gallery

- Related Products

1. It uses an eccentric block as the excitation source, with strong excitation force, high screening efficiency and large processing capacity.

2. It uses low-stress shock-absorbing springs, which makes the vibrating screen operate with low noise and low power consumption;

3. It uses super heavy-duty large oil clearance bearings with low operating temperature and long service life;

4. It adopts ring-groove rivets and modular screen box frame structure, with high structural strength;

5. It can be equipped with polyurethane meshes, which can make jammed materials jump out and prevent the meshes from clogging;

6. It has a simple structure, strong parts versatility, and easy maintenance.

7. It adopts flexible connections such as cross-axis universal coupling or rubber coupling to ensure smooth operation.

| Model | Decks | Mesh area (㎡) | Vibration frequency (rpm) | Vibration amplitude (mm) | Capacity (t/h) | Power(kw) | Dimensions (mm) |

| YK1548 | 2 | 7.2 | 800-900 | 6-8 | 45-380 | 15 | 5573×2110×1582 |

| 3 | 15 | 5610×2110×1776 | |||||

| 4 | 18.5 | 5798×2110×2191 | |||||

| YK1860 | 2 | 10.8 | 75-600 | 22 | 6596×2510×1583 | ||

| 3 | 22 | 6759×2510×1583 | |||||

| 4 | 30 | 6828×2510×2375 | |||||

| YK2160 | 2 | 12.6 | 85-700 | 30 | 6596×2810×1580 | ||

| 3 | 30 | 6765×2810×2025 | |||||

| 4 | 37 | 6912×2810×2380 | |||||

| YK2460 | 2 | 14.4 | 100-800 | 30 | 6693×3110×1587 | ||

| 3 | 30 | 6758×3110×2027 | |||||

| 4 | 37 | 6905×3110×2027 | |||||

| YK2475 | 2 | 18 | 130-1000 | 30 | 7942×3120×1578 | ||

| 3 | 37 | 8124×3120×2020 | |||||

| 4 | 45 | 8350×3120×2285 | |||||

| YK3075 | 2 | 22.5 | 8-10 | 165-1250 | 55 | 8229×3776×1784 | |

| 3 | 55 | 8378×3776×2190 | |||||

| 4 | 75 | 8465×3776×2399 | |||||

| YK3680 | 2 | 28.8 | 220-2100 | 37×2 | 8730×4380×1990 | ||

| 3 | 37×2 | 8880×4380×2390 | |||||

| 4 | 45×2 | 8970×4380×2610 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

PXJ Fine hammer crusher

PXJ Fine hammer crusher

PL Composite vertical shaft crusher

PL Composite vertical shaft crusher

V Vertical shaft impact crusher

V Vertical shaft impact crusher

PF Impact crusher

PF Impact crusher

FAQ

Q: What is the difference between a inclined screen and a horizontal screen?

A: 1) Screening trajectories. The horizontal vibrating screen uses the excitation force of the vibration motor to throw the materials on the screen and advance in a straight line. The inclined vibrating screen uses the centrifugal force generated by the rotation of the eccentric block to force the screen box, vibrator and other components to perform forced continuous circular or approximately circular motion.

2) Exciters. The horizontal vibrating screen exciter consists of two shafts. It uses the principle of vibration motor excitation, so it is also called a double-axis vibrating screen. Inclined vibrating screen is also called single-axis vibrating screen because its vibrator is single-axis and uses an inertia motor to work.

3) Installation inclinations. Generally speaking, the inclination of the inclined vibrating screen is larger than that of the horizontal vibrating screen, generally around 15-20 degrees. This can change the moving speed and bouncing strength of materials along the screen, thereby reducing blocking and improving efficiency.

4) Materials. Horizontal vibrating screens are mainly made of lightweight plates or stainless steel plates. Inclined vibrating screen is made of thick material. The screening box is made of manganese steel, which can resist the impact of materials during the screening process.

5) Applications. The horizontal vibrating screen is more suitable for assembly line operations; it is suitable for screening powdery, fine-grained or micro-powder materials, and is usually used in food, chemical, pharmaceutical and other industries. The inclined vibrating screen mainly screens materials with large particles, heavy specific gravity and high hardness. It is usually used in mining, coal and other industries, so it is also called a mining screen.

Q: What are the precautions for safe operation, maintenance and cleaning of inclined vibrating screens?

A: 1) Safe operation.

1-1. Before use, check whether the ground wire of the equipment is intact and whether the electrical system meets the specifications.

1-2. Operators must wear work clothes that meet safety requirements and properly wear protective equipment such as hard hats and gloves.

1-3. During cleaning, maintenance, mesh replacement and other operations, the power must be cut off and locked to ensure personnel safety.

1-4. It should be ensured that no one is around the workplace when the vibrating screen is working. If there are people, effective isolation should be carried out to prevent debris from falling into the equipment.

1-5. For abnormal sounds, vibrations or other abnormal conditions, stop the equipment immediately to check and troubleshoot.

2) Maintenance.

2-1. All parts of the equipment, such as motors, seals, bearings, etc., should be checked regularly to see if they are functioning properly.

2-2. Parts, such as meshes, springs, etc., should be replaced in time to ensure normal operation of the equipment.

2-3. During operation, attention should be paid to monitoring the temperature and bearing lubrication conditions, and problems should be dealt with promptly.

2-4. After the equipment is shut down, it should be cleaned in time to avoid material clogging or accumulation on the screen, which will affect the normal operation of the equipment.

3) Cleaning.

3-1. After stopping the operation of the equipment, you should first clean up the garbage and debris on the surface of the equipment and its surrounding areas.

3-2. After each use, the equipment should be cleaned and wiped promptly to avoid accumulation of dirt that affects the screening effect.

3-3. When cleaning, be careful not to use too hard or sharp objects to avoid scratching the surface of the equipment.

3-4. When cleaning, be careful not to let water splash into the interior of electrical appliances and other equipment to avoid affecting the safety performance and service life of the equipment.