- Features & Properties

- Technical Specification

- Gallery

- Related Products

1. Integrity and convenience. Its integrated group working method eliminates the complex foundations and auxiliary facilities required for separate plants, and reduces the consumption of materials and labor. Its reasonable and compact layout optimizes the space where the plant is stationed and expands the space for material stacking and transfer.

2. Mobility and flexibility. The wheeled mobile crushing and screening plant has a high chassis and a small turning radius, making it easy to drive on ordinary roads and even in rugged and harsh road environments in workplace areas. In this way, it saves time for quick entry and provides a flexible working space for the entire plant.

3. Shipping costs saving. In line with the principle of being as close as possible to material processing, it can perform first-line on-site crushing and screening of materials. In this way, it eliminates the need to first transport and then crush and screen materials due to being far away from the site, which greatly reduces the transportation costs.

4. Directness and effectiveness. The wheeled mobile crushing and screening plant can be used independently, or it can form a more flexible solution based on material type and discharge size to meet different requirements. In this way, organization, transshipment, and logistics are more direct and effective, and costs are minimized.

5. Adaptability and versatility. It provides simple, low-cost personalized solutions. A single plant can work independently or multiple plants can work together. Side-offset belt conveyors provide flexibility for conveying screened materials. In addition, it can be equipped with an optional diesel generator set for power supply.

6. Reliability and maintainability. It can be configured with various crushers and other machines to improve efficiency, with multi-function and excellent effects. It has a lightweight and reasonable structural design, reliable and stable quality assurance, and can meet different crushing and screening requirements to the greatest extent.

Tracked mobile crushing and screening plants

Tracked mobile crushing and screening plants

PEC Jaw crusher

PEC Jaw crusher

Stationary crushing and screening plants

Stationary crushing and screening plants

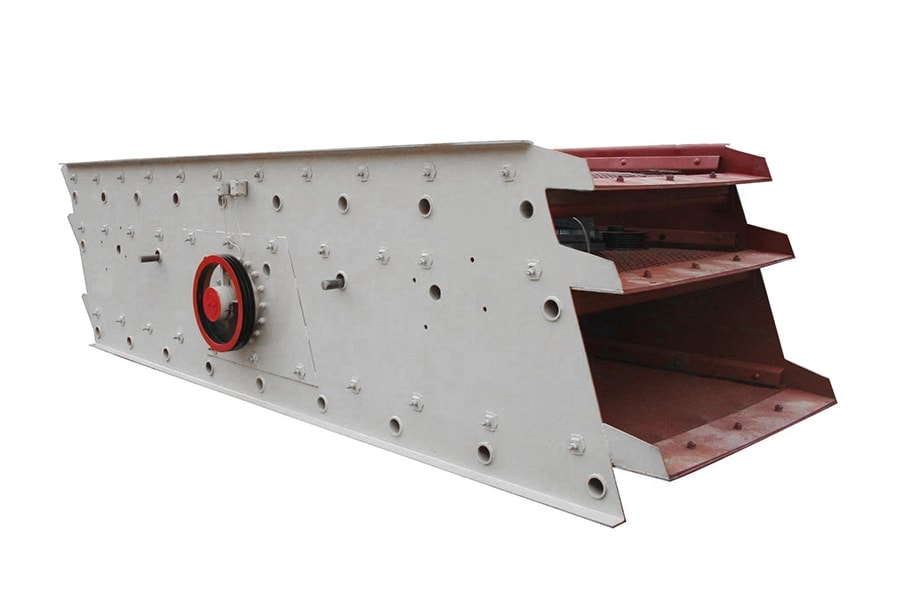

YK Vibrating screen

YK Vibrating screen

FAQ

Q: What is the difference between a mobile crushing and screening plant and a stationary crushing and screening plant?

A: 1) Flexibility. Mobile crushing and screening plant is a combined mobile equipment composed of crusher, screen, belt conveyor, chassis and other accessory parts. In fact, it is a flexible crushing and screening plant, while the equipment in the stationary plant requires concrete foundations. To sum up, the main difference between the two is flexibility.

2) Price. The price of the stationary crushing and screening plant is lower than that of the mobile plant, with simple design and low investment. Commonly used crushers include jaw crusher, impact crusher, cone crusher, hammer crusher, VSI crusher, roller crusher, etc. Mobile plants can be matched with different types of crushers.

3) Advantage. Both stationary and mobile plants have their own advantages, depending on the needs of the user. Mobile plants are suitable for small and medium-sized projects that require frequent transfers. For stationary plants, the foundation needs to be redone if moved, so it is suitable for large and long-term projects.

Q: What should we pay attention to during the transportation of wheeled mobile crushing and screening plant?

A: Wheeled mobile crushing and screening plant is a large-scale equipment and is generally towed and transported by trucks. In order to ensure that it is delivered to the customer's site safely and smoothly, we need to pay attention to the following matters during transportation:

1) The accessories on the plant should be removed before long-distance transportation, and the movable parts should be fixed to prevent impact and vibration when traveling at high speed;

2) If the size of the plant is too large and exceeds the regulations of the transportation authority, the transportation plan should be carefully designed with the transportation authority;

3) Before official transportation, a comprehensive inspection of the mobile plant should be carried out, especially the traction lights and brake lights, to prevent safety accidents;

4) After preparation is complete, the support legs should be stowed;

5) When the plant is transported over a short distance at the working site, the preparation work is relatively simple. The main task is to check the walking device as needed.

6) All parts must be counted to prevent any omissions when delivered to the customer's site;

7) Find a regular logistics company and ensure that the qualification certificate of the towing truck is complete to ensure the reliability of the transportation of the mobile plant;

8) During transportation, the speed should not be too fast and clear signs should be set up.