- Features & Properties

- Technical Specification

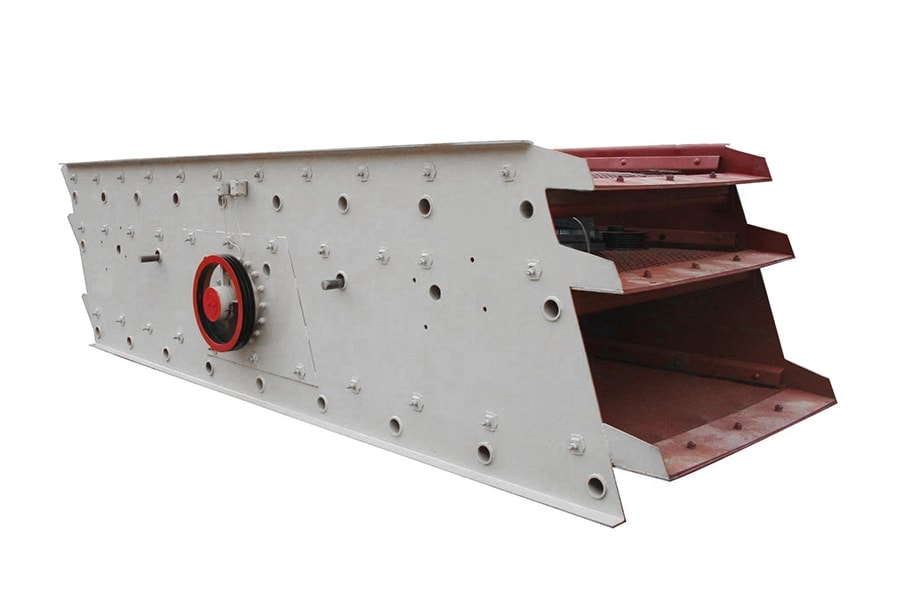

- Gallery

- Related Products

1. The structure is simple, and the drive bearing is isolated from water and materials, which greatly avoids damage to the bearings due to water immersion, sand and pollutants.

2. This sand washer has almost no wearing parts except the mesh.

3. The sand washer has a long service life and does not require maintenance for a long time.

| Model | Wheel diameter (mm) | Speed (rpm) | Capacity (t/h) | Recovery capacity (t/h) | Power(kw) |

| WS2610 | 2600 | 2.5 | 20-70 | 5-20 | 5.5 |

| 2WS2612 | 2600 | 2.5 | 30-90 | 8-30 | 7.5 |

| 2WS2812 | 2800 | 1.2 | 60-150 | 20-50 | 7.5 |

| 2WS2816 | 2800 | 1.2 | 160-250 | 50-120 | 11 |

| 2WS3016 | 3000 | 1.2 | 200-280 | 80-130 | 11 |

| 2WS3216 | 3200 | 1.2 | 240-300 | 100-150 | 11 |

| 2WS3620 | 3600 | 1 | 280-400 | 140-200 | 15 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

FAQ

Q: What are the application scope and characteristics of waterwheel sand washer?

A: When the waterwheel sand washer is working, the motor drives the wheel to rotate slowly through the V-belt, reducer and gear. The sand enters the washing tank from the feeding trough, tumbles under the drive of the wheel, and grinds each other to remove impurities covering the surface of the sand, and at the same time destroys the water vapor layer coating the sand to facilitate dehydration; Add water at the same time to form a strong water flow, which can promptly take away impurities and foreign objects with small specific gravity and discharge them from the overflow outlet. The clean sand is taken away by the wheel, and finally the sand is poured from the rotating wheel into the discharge trough, thus completing the sand cleaning.

The waterwheel sand washer has a simple structure, and the drive bearing is isolated from water and materials, which greatly avoids damage to the bearing due to water immersion, sand and pollutants. It has obvious advantages over traditional spiral sand washers when used for sand washing in aggregate yards.

Q: What are the advantages and disadvantages of waterwheel sand washer and spiral sand washer?

A: 1) Advantages and disadvantages of waterwheel sand washer.

Advantages: The amount of water required is smaller; Simple operation and easy maintenance; Suitable for a variety of sand and gravel sizes;

Disadvantages: The washing effect is worse than that of spiral sand washer; It requires a large amount of water spray, so it produces a lot of noise; It is easy to cause sand loss during the washing process.

2) Advantages and disadvantages of spiral sand washer.

Advantages: Good washing effect; Less noise; The content of mud and sand can be adjusted according to the working status.

Disadvantages: Large water consumption and high water pressure requirements; Maintenance is more complex; Suitable for finer sand and gravel.

3) Suggestions for selection.

Waterwheel sand washers and spiral sand washers each have their own advantages and disadvantages, and which one you choose depends on your specific needs. If the sand and gravel you want to wash are of larger particle size, it is suitable to choose a waterwheel sand washer, which is easy to maintain and easy to operate. If you need to wash finer sand and gravel, or need better washing results, a spiral sand washer is a good choice. However, it should be noted that due to the good cleaning effect of the spiral sand washer, the maintenance is more complicated, so you need to fully understand the use and maintenance methods before purchasing.