- Features & Properties

- Technical Specification

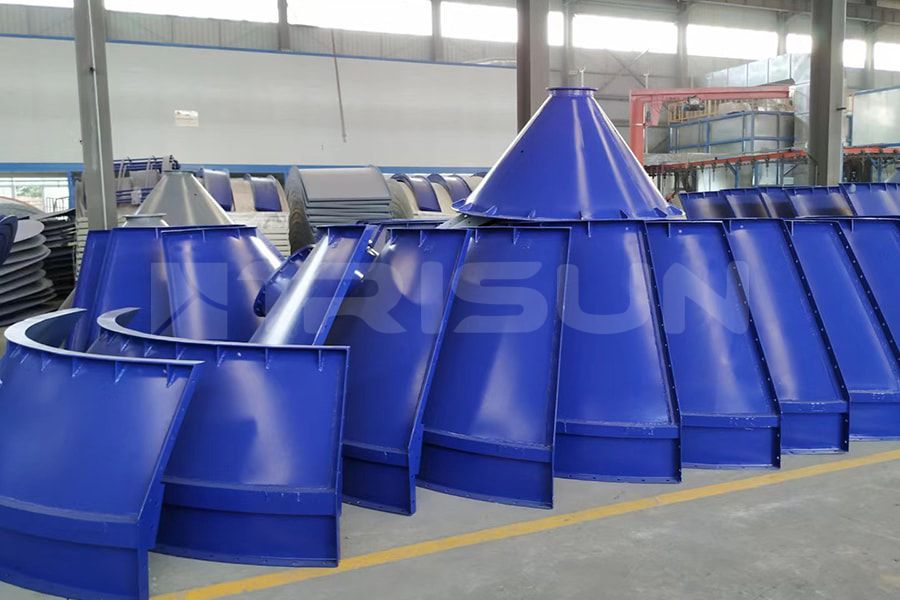

- Gallery

- Related Products

1. Flexible configuration, the diameter and height of the bolted cement silo can be designed as needed.

2. Large storage capacity. A single silo can store 30-2000 tons, and a large-capacity storage group can be formed.

3. Multifunctional. The bolted cement silo can be used to store cement, fly ash and other powder materials.

4. Easy to install and dismantle. It can be loaded into containers, which greatly reduces transportation and disassembly costs.

5. Good sealing. Made in the factory with precision machinery, ensures moisture resistance when storing bulk materials.

6. It occupies a small area and is recyclable. When it needs to be used in other places, only the sealing strip and some bolts need to be replaced.

| Model | Capacity | Diameter | Height without supporting legs | Suggested screw conveyor model |

| SV30 | 30T | 2.5m | 4.8m | Φ163 |

| SV50 | 50T | 3m | 5.4 | Φ219 |

| SV80 | 80T | 3m | 9.0 | Φ219 |

| SV100 | 100T | 3m | 11.4 | Φ219 |

| SV150 | 150T | 3m | 23.5 | Φ219 |

| SV200 | 200T | 4.5m | 18.6 | Φ273 |

| SV300 | 300T | 4.5m | 24.6 | Φ325 |

| SV500 | 500T | 6m | 22.2 | Φ325 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

YHZ Mobile concrete plant

YHZ Mobile concrete plant

HZ Stationary concrete plant

HZ Stationary concrete plant

UM Underground concrete mixer

UM Underground concrete mixer

CM Concrete mixer truck

CM Concrete mixer truck

FAQ

Q: How to choose the appropriate cement silo?

A: In order to ensure that the cement silo can meet the demand for cement in concrete plants or construction projects, improve production efficiency, and ensure project safety, the dimensional parameters of the cement silo should be mainly considered when selecting a cement silo, including height, diameter, bottom inclination, and wall thickness.

1) Cement silo height. The height of the cement silo depends on the required capacity and space constraints. Generally speaking, the height of cement silos generally does not exceed 18 meters. This is because a silo that is too high will increase pressure and instability.

2) Cement silo diameter. The diameter is also determined based on the required capacity and space constraints. Common cement silos have a diameter of 3-30 meters. It should be noted that if the diameter is too small, frequent discharging will be required, which will affect production efficiency.

3) Silo bottom inclination. The bottom inclination of the cement silo is related to the fluidity. If the bottom inclination is too large, it will cause cement to accumulate as it flows, especially when it is transported downward. The most common bottom inclination is 55 degrees, which is sufficient for most needs.

4) Silo wall thickness. The wall thickness of the cement silo can be adjusted according to the required capacity and geological conditions. Geological conditions need to be taken into consideration when selecting the appropriate wall thickness to ensure the stability and safety of the cement silo. Common wall thicknesses are 3mm to 10mm.

Q: How are cement silos manufactured by TRISUN connected? What are the advantages?

A: Currently, the cement silos on the market include integral cement silos and bolted cement silos, but those used for export are generally bolted silos. It has the characteristics of reasonable design, simple structure, flexible and convenient assembly, high assembly efficiency, long service life, small size and convenient transportation.

Q: What is the operation process of bolted cement silo?

A: 1) When the bolted cement silo is assembled, it must be erected by a special crane and then placed on the prefabricated concrete foundation. The perpendicularity of the erected cement silo to the horizontal plane must be checked, and then the bottom of the bolted cement silo must be pre-assembled with the foundation. Embedded parts should be welded firmly.

2) After the cement silo is fixed, the bulk cement truck transports the cement to the construction site, and then connects the bulk cement truck's delivery pipeline to the cement silo's feed pipe. The cement in the bulk truck is transported to the cement silo through the gas pressure.

3) During the process of transporting cement into the cement silo, the operator must continuously press the button of the vibration motor of the dust collector to shake off the cement attached to the dust collector bag to prevent explosions caused by the bag being blocked.

4) Once the bag is blocked and the pressure in the cement silo exceeds the safety value of the pressure safety valve on the top of the cement silo, the valve can be opened to release the pressure in the cement silo to prevent the occurrence of cement silo explosion accidents.

5) Whether the cement silo is full or short of material can be observed through the level meters.

6) When it is necessary to discharge, first open the manual valve at the bottom of the cone, and then transport the cement out through the cement conveying device (screw conveyor). During the discharging process, if agglomeration occurs, press the button of the solenoid valve of the arch breaking device in time to blow air to eliminate cement agglomeration for feeding and ensure smooth cement supply.

When the cement conveying device (screw conveyor) fails, first close the manual discharge valve at the bottom of the cone to prevent cement from overflowing and causing waste.