- Features & Properties

- Technical Specification

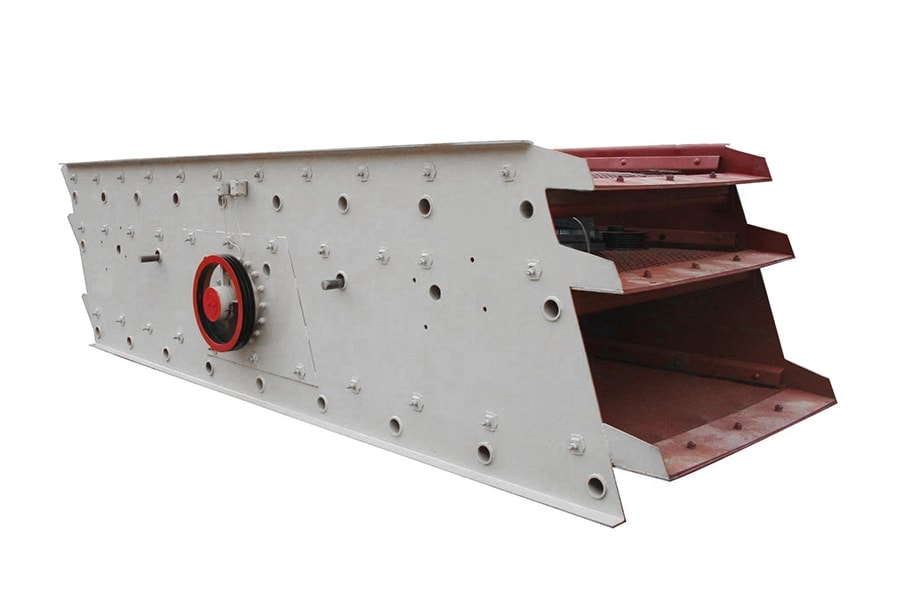

- Gallery

- Related Products

1. Low noise and less pollution: The working noise is less than 75 decibels and there is very little dust pollution.

2. High sand formation rate: The yield of products below 5mm is as high as over 95%, and the discharge particle size can be adjusted arbitrarily.

3. Strong and durable: The hammer is made of forged and wear-resistant alloy, with long wear cycle and long service life.

4. Wide range of applications: The composite vertical shaft crusher has no screen bars and is not easy to block when crushing materials with high moisture content and large mud content.

| Model | Maximum feeding size (mm) | Main shaft speed (rpm) | Capacity (t/h) | Power(kw) | Dimensions (mm) |

| PL800 | 100 | 800-1350 | 8-20 | 45 | 2370×1150×1300 |

| PL1000 | 120 | 650-980 | 15-30 | 55 | 2600×1420×1520 |

| PL1250 | 150 | 510-770 | 35-45 | 90 | 3070×1690×1660 |

| PL1500 | 180 | 430-640 | 50-70 | 132 | 3390×2050×2030 |

| PL1750 | 200 | 420-540 | 70-100 | 200 | 3820×2360×2080 |

| PL2000 | 220 | 360-500 | 90-120 | 250 | 4080×2610×2180 |

| PL2300 | 240 | 330-450 | 120-160 | 160×2 | 4472×2930×2554 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

FAQ

Q: What is the difference between composite vertical shaft crusher (PL) and vertical shaft impact crusher (VSI)?

A: 1) Feeding method. The feeding method of PL crusher is center feeding, while VSI crusher has two feeding modes: center feeding and center feeding with ring feeding. In addition to two feeding methods, the VSI crusher also has two crushing methods: rock against rock and rock against metal. Among them, rock against rock is suitable for shaping, and rock against metal is suitable for sand making.

2) Wear resistance of wearing parts. The single feeding method of PL crusher determines the short life of its wearing parts, while VSI crusher is different: With its two-in-one feeding method, its wearing parts have a longer working life and higher economic benefits; The optimized arrangement of wear-resistant materials increases the service life by more than 40% and reduces the cost by more than 40%; In addition, during the production process, the stone can form a protective layer, making the machine less wear-and-tear and durable.

3) Opening method. The PL crusher does not have a frame opening and inspection mechanism, which is time-consuming and laborious to repair. The VSI crusher is equipped with an automatic inspection and opening mechanism. The crusher can be inspected by opening the frame, saving time and effort, and greatly reducing maintenance costs.

4) Lubrication system. The PL crusher uses a grease lubrication system with poor heat dissipation performance, which greatly reduces the service life of the main shaft bearing and increases maintenance costs. The VSI crusher adopts a light oil lubrication system, which can effectively dissipate heat during the operation of the main shaft bearing, ensuring that the temperature rise is within 25°C and extending the service life of the bearing. During the working process, the light oil system can effectively lubricate and reduce bearing friction, increase bearing speed, thereby greatly improving work efficiency.

5) Manufacturing process. The PL crusher adopts the profile welding process, which makes the production and selection of materials simple and the structural strength is relatively poor. The VSI crusher adopts the steel plate bending hot rivet process, which has a more environmentally friendly appearance, enhances the structural strength and toughness of the equipment, and ensures the smooth operation of the equipment.

6) Crushing cavity. The PL crusher uses a shallow rotor. This cavity shape greatly reduces the processing capacity of the equipment when producing materials, which results in low production capacity of the equipment. Relatively speaking, the deep rotor used by the VSI crusher can greatly improve the equipment's material processing capacity.

7) Distributing cone (disc). The PL crusher does not have a distributing device. Its working principle is to use rock against rock to complete the sand making function. The VSI crusher is equipped with a distributing cone (disc), which can easily achieve the effects of shaping and sand making by adjusting the proportion of materials entering the rotor and vortex chamber according to the user's shaping or sand making needs. Achieve the multi-purpose effect of one machine.

8) Shape of discharged material. With the increasing development of manufactured sand technology, the VSI crusher is less affected by the moisture content of the material, which can reach 8%. Moreover, the products it discharges have excellent shape, in the form of cubes, with extremely low needle-flake content, high bulk density, and low iron pollution. They are suitable for aggregate shaping, manufactured sand and high-grade highway aggregate production. The sand produced is both the gradation and the fineness modulus meet the national standard.

9) Environmental protection effect. Traditional PL crushers do not consider too many environmental factors. In recent years, with the improvement of environmental protection requirements and the strengthening of penalties for environmental pollution, the design of VSI crusher can better meet the current market requirements. Because it is an internal cavity crusher, it has less dust pollution and low working noise.

Q: What precautions should be taken during the operation of the composite vertical shaft crusher?

A: 1) Under normal circumstances, the temperature rise of the bearing does not exceed 35°C and the temperature does not exceed 70°C. If it exceeds 70°C, the machine should be stopped immediately to find out the cause and eliminate it.

2)When the crusher is running, it is strictly prohibited to open the inspection door to check the conditions inside the machine, and it is strictly prohibited to perform any adjustment, cleaning and maintenance work to avoid danger.

3)The equipment generates a lot of dust during operation. In addition to sealing all parts of the crusher, ventilation and dust collection equipment should also be installed in the workshop.

4)During the operation of the equipment, the feeding should be uniform, and excessive feeding should not be allowed, otherwise clogging will occur, which will also reduce the production capacity of the equipment and increase the consumption of the spindle.