- Features & Properties

- Technical Specification

- Gallery

- Related Products

Continuous plant

1) It has a compact structure and small footprint, and can be used in narrow places.

2) Easy to transport and relocate, equipped with a chassis that can be towed with a trailer.

3) The batching hopper is equipped with a weighing sensor and a motor with a frequency converter, which can be remotely controlled and the cold aggregate ratio is accurate.

4) The drying drum integrates drying, heating and mixing, with less heat loss; the internal structure is optimized, the heating speed is fast, and the mixing effect is good.

5) Low initial investment and high cost performance.

Intermittent plant

1) Modularly designed, the main modules are equipped with chassis, allowing for quick relocation and installation;

2) High-precision screening, accurate measurement, batch mixing, and high-quality finished asphalt concrete;

3) The drying drum and mixing drum are optimized with good performance; key components are made of wear-resistant materials with longer service life;

4) The structure is simple and the floor space is small.

5) PLC system, automatic control, easy to operate.

6) Each module is equipped with an independent electrical cabinet, which is convenient and reliable.

| Model | Nominal capacity | Mixer capacity | Total power | Fuel consumption | ||

| Fuel coal | Fuel oil | |||||

| Continuous | YSLB20 | 20t/h | - | 40kW | 10kg/t | 5.5-7kg/t |

| YSLB40 | 40t/h | - | 75kW | 10-13kg/t | 5.5-7kg/t | |

| YSLB60 | 60t/h | - | 128kW | 10-13kg/t | 5.5-7kg/t | |

| YSLB80 | 80t/h | - | 165kW | 10-13kg/t | 5.5-7kg/t | |

| YSLB100 | 100t/h | - | 200kW | 10-13kg/t | 5.5-7kg/t | |

| Intermittent | YLB700 | 60t/h | 750kg | 157kW | 10kg/t | 5.5-7kg/t |

| YLB1000 | 80t/h | 1000kg | 241kW | 10kg/t | 5.5-7kg/t | |

| YLB1500 | 120t/h | 1500kg | 330kW | 10kg/t | 5.5-7kg/t | |

| YLB2000 | 160t/h | 2000kg | 412kW | 10kg/t | 5.5-7kg/t | |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

YHZ Mobile concrete plant

YHZ Mobile concrete plant

YWB Mobile Soil stabilization plant

YWB Mobile Soil stabilization plant

LB Stationary Asphalt plant

LB Stationary Asphalt plant

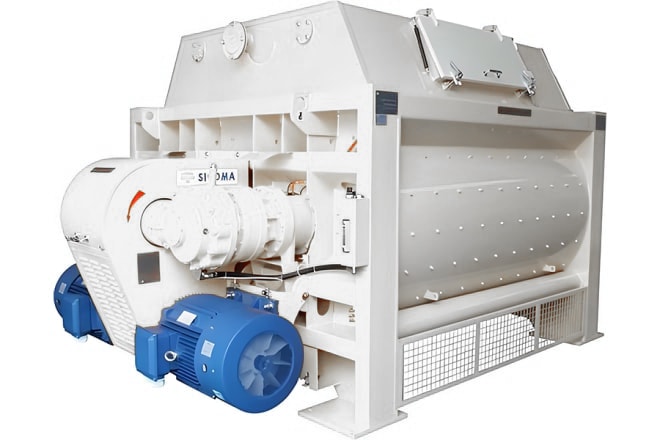

MAO Twin-shaft mixer

MAO Twin-shaft mixer

FAQ

Q: What are the safety precautions during the operation of asphalt plant?

A: 1) Personnel clothing

Personnel working in asphalt plant must wear work clothes and safety helmets as required. Slippers are strictly prohibited during operation of asphalt plants.

2) During the operation

Before starting the asphalt plant, the operator in the control room must sound the horn to warn. When the surrounding staff hear the sound of the horn, they should immediately leave the dangerous area. The operator can only start the plant after confirming that the people outside are in a safe condition.

During the loading process, it is necessary to keep an eye on the position of the truck, so as to effectively ensure safety. While the machine is in operation, no one is allowed to perform unauthorized maintenance on it. Only when safety is ensured can the machine be repaired, and machine repairs must be made known to the operator in the control room.

Q: What are the advantages of mobile asphalt plants over traditional stationary asphalt plants?

A: 1) High mobility: The mobile asphalt plant adopts a chassis design and can be moved to the place where production is needed at any time, which is convenient and fast.

2) High flexibility: The mobile asphalt plant has a small capacity and is suitable for small projects and temporary construction sites; the number of equipment can be increased or decreased at any time to flexibly respond to production needs.

3) Easy installation: The mobile asphalt plant does not require a concrete foundation, is simple and easy to install, and takes a relatively short time.

4) Cost saving: Mobile asphalt plants do not require a fixed site and can significantly reduce the total investment cost for projects with high uncertainty or that require frequent changes in construction locations.

Q: Should I choose a stationary asphalt plant or a mobile asphalt plant?

A: Choosing between the two is fairly easy: Do you need to move your asphalt plant? If so, how often does it move? An undoubted fact is that the cost of a mobile asphalt plant is slightly higher than a stationary one. If you only need to move your plant every few years, a stationary plant would be a more suitable choice. And companies that plan to move their asphalt plant times a year must purchase a mobile plant.

Q: How to choose a suitable asphalt mixing plant?

A: When you decide to buy an asphalt plant and start producing asphalt concrete for yourself, or for commercial sales, you must choose the type, size, brand and budget of the asphalt plant. Subsequently, the corresponding storage size, number of cold material hoppers, type of contamination control, etc. must also be considered. In any case, if you want to get a suitable mobile asphalt plant, then the first thing you need to do is to choose a reputable mobile asphalt plant supplier. There are many mobile asphalt plant manufacturers on the market, but you need to make a detailed comparison before making a decision. TRISUN comes from China and is a reliable supplier of mobile asphalt plants. TRISUN has many types of mobile asphalt plants, stationary asphalt plants, drum continuous asphalt plants, forced intermittent asphalt plants, etc. We sincerely welcome you to contact us and get detailed information, we will give you the best price and service.