- Features & Properties

- Technical Specification

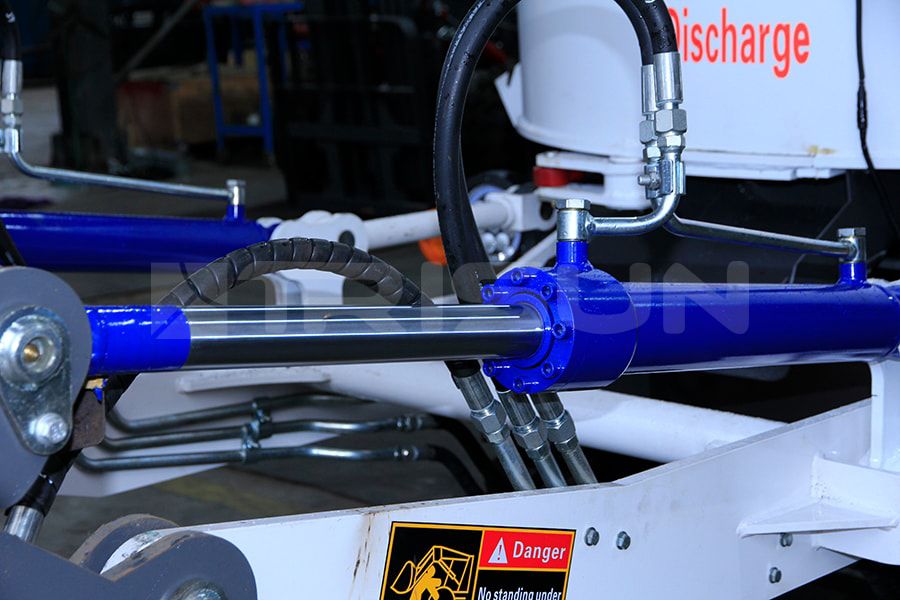

- Gallery

- Related Products

1. Automatic loading and water filling: It is equipped with a feeding bucket and an automatic water supply device, and can move while mixing, improving efficiency.

2. Suitable for different terrains: It does not rely on electricity and is suitable for different terrains, including mountain roads, wetlands and other complex conditions.

3. High production speed: It has a high discharging speed of 7.5 minutes per batch on average, which improves production efficiency.

4. Model can be customized: The model can be customized according to the capacity required by the customer to meet different needs.

| Model | LSM1.2 | LSM2.0 | LSM2.5 | LSM3.5 | LSM4.0 | LSM5.5 | LSM6.5 |

| Nominal capacity |

1.1m³/batch 9m³/h |

1.9m³/batch 15m³/h |

2.3m³/batch 18m³/h |

3.2m³/batch 26m³/h |

4.0-m³/batch 32m³/h |

5.2m³/batch 42m³/h |

6m³/batch 48m³/h |

| Mixer geometric capacity | 1700L | 2860L | 3580L | 4740L | 6000L | 7800L | 9000L |

| Chassis | Articulated | Articulated | Articulated | Articulated | Articulated | Articulated | Articulated |

| Engine brand | Yunnei/Yuchai/Cummins | Yunnei/Yuchai/Cummins | Yunnei/Yuchai/Cummins | Yuchai/Cummins | Yuchai/Cummins | Xichai/Yuchai | Weichai/Cummins |

| Engine power | 75-100HP(55-74kW) | 100-106HP(74-78kW) | 100-125HP(74-92kW) | 115-125HP(85-92kW) | 115-125HP(85-92kW) | 150HP(110kW) | 125HP(92kW) |

| Weight | 4185kg | 6500kg | 6500kg | 7500kg | 9000kg | 11200kg | 12520kg |

| Overall size | 6400x2550x3300mm | 7300x2650x 3750mm | 7860x2750x4100mm | 7830x2680x4170mm | 7640x2870x4750mm | 8450x3100x4580mm | 8450x3050x4830mm |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

YHZ Mobile concrete plant

YHZ Mobile concrete plant

TSM Self-loading concrete mixer

TSM Self-loading concrete mixer

JBT Concrete mixer with pump

JBT Concrete mixer with pump

CM Concrete mixer truck

CM Concrete mixer truck

FAQ

Q: What projects is the vertical shaft self-loading concrete mixer suitable for?

A: Vertical shaft self-loading concrete mixers are widely used in various engineering projects, including but not limited to:

Construction projects: highways, power stations, dam construction projects, construction sites, roads, bridges and other projects.

Rural construction: roads, building renovations, electric pile pouring, high-standard farmland water conservancy pouring, etc.

Q: What are the advantages of vertical shaft self-loading concrete mixers in application?

A: 1) High efficiency and low consumption: It has the advantages of low consumption, smooth operation, compact structure, light weight, and high efficiency. These characteristics enable it to play an important role in various projects such as highways, power stations, construction sites, damming projects, hydropower, roads, bridges and large and medium-sized prefabricated plants.

2) Simple operation and easy to use: It does not require skilled operators and can be used after simple training, which makes it very suitable for private use and can greatly save manual labor. At the same time, its small size and lightness also make it very convenient to move and transport.

3) Low price and broad market prospects: Its price is low, so its use limitations are small and its market prospects are broad, which makes it widely used in various engineering projects, whether in large construction sites or small rural road construction.

4) Save labor and reduce labor intensity: It can save labor costs and reduce labor intensity, mainly because it can integrate mixing, transportation, loading and unloading into one machine, making it a multi-purpose machine.

Q: What are the main operating steps of a vertical shaft self-loading concrete mixer?

A: 1) Start the engine of the vertical shaft self-loading mixer and ensure that all equipment are running normally.

2) Load concrete into the mixing tank. The opening design of the mixing tank facilitates loading and maintenance.

3) Start the mixing device to mix. The mixing condition needs to be constantly checked to ensure uniform mixing.

4) After the mixing is completed, drive the self-loading mixer to the required place to unload the concrete.

5) After unloading, flush the inside of the mixing tank with water to prevent the concrete from hardening inside.

Q: What are the precautions for use and maintenance of vertical shaft self-loading concrete mixer?

A: 1) Before use, the remaining accumulated water and debris in the mixing drum should be drained to prevent concrete segregation.

2) It must be rotated continuously during transportation to prevent concrete from segregating.

3) During transportation, the driving speed must not exceed 40km/h.

4) The pressure of the hydraulic system should comply with the regulations in the instruction manual and should not be adjusted at will. The quality and quantity of the hydraulic oil should comply with the original requirements.

5) When the ambient temperature is higher than 25 degrees Celsius, the duration from loading, transportation, and unloading shall not exceed 60 minutes.

6) During winter construction, check whether there is ice before starting the machine, and drain the remaining water in the mixing drum and water supply system when leaving get off work. Turn off the water pump switch and place the control handle in the "Stop" position.