- Features & Properties

- Technical Specification

- Gallery

- Related Products

1. High crushing efficiency, with functions of fine crushing and coarse grinding;

2. Simple structure, easy installation and maintenance, and low operating cost;

3. Strong ability to pass through non-processable materials, little affected by the moisture content of the materials.

4. The discharge shape is cubic, with very low needle and flake content, very suitable for aggregate shaping and sand making;

5. The discharged material has a high packing density and minimal iron contamination.

| Model | Maximum feeding size (mm) | Capacity (t/h) | Power(kw) | ||

| Crushing | Shaping | Crushing | Shaping | ||

| V8015 | 30 | 40 | 109-117 | 131-140 | 75×2 |

| V9518 | 35 | 45 | 135-147 | 165-185 | 90×2 |

| V9526 | 40 | 50 | 167-179 | 200-215 | 132×2 |

| V9532 | 40 | 50 | 198-210 | 232-248 | 160×2 |

| V1140 | 45 | 55 | 264-283 | 317-342 | 200×2 |

| V1145 | 45 | 55 | 304-325 | 366-393 | 220×2 |

| V1150 | 45 | 55 | 344-368 | 413-442 | 250×2 |

| V1263 | 50 | 60 | 454-486 | 545-583 | 315×2 |

Note: All features, functionality and other product specifications are subject to change without notice or obligation.

PXJ Fine hammer crusher

PXJ Fine hammer crusher

PL Composite vertical shaft crusher

PL Composite vertical shaft crusher

WS Waterwheel sand washer

WS Waterwheel sand washer

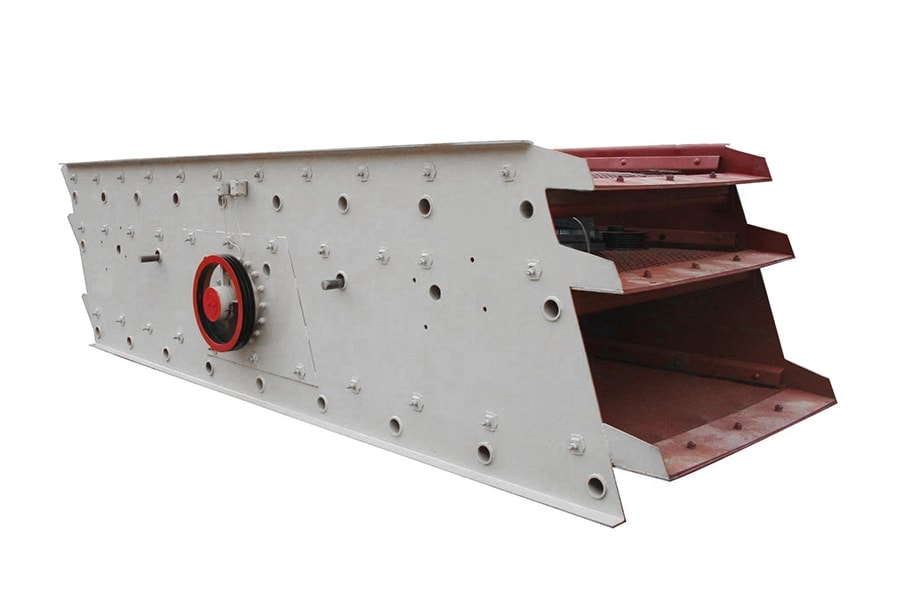

YK Vibrating screen

YK Vibrating screen

FAQ

Q: What are the characteristics of the operation of vertical shaft impact crusher?

A: 1) Simple structure and low cost;

2) Energy saving and high crushing efficiency;

3) With fine crushing and coarse grinding functions;

4) It has high passability for non-processable materials and is less affected by the moisture content of the materials.

5) Can crush medium hard and extra hard materials (such as corundum, sintered bauxite, etc.);

6) The discharged product is cube-shaped with little iron pollution;

7) The accumulation of materials in the rotor and crushing cavity can greatly reduce the cost of wearing parts and the workload of maintenance;

8) Easy to operate, maintain and install;

9) The working noise is less than 75 decibels;

10) Light weight, diverse installation methods, can be installed mobile.

11) The structure is novel and unique, and the operation is smooth.

Q: Why is the vertical shaft crusher also called sand maker? What are the advantages of manufactured sand compared to natural sand?

A: Vertical shaft impact crusher, also known as sand maker, is an important equipment for sand making and shaping. The original intention of developing the vertical shaft impact crusher was to solve the problems of poor shape and excessive needle and flake shapes produced by traditional spring cone. The raw materials for manufactured sand are usually granite, basalt, river pebbles, limestone, construction solid waste, etc. Although the finished sand made from different raw materials will be different, manufactured sand has the following advantages over natural sand:

1) The finished product is of good quality, with less soil and other impurities, high hydrophilicity, and complete classification.

2) Fixed source of raw materials, mechanized production, adjustable and controllable particle size, ensuring the stability of product quality.

3) The raw materials are widely available and can be obtained locally, and can be produced using various ore resources and even waste resources.

Q: What is the process flow of manufactured sand?

A: 1) Preprocessing. If limestone, bluestone, river pebbles, granite and other sand-making raw materials contain too much soil and impurities, the debris that is not suitable for crushing can be sorted first, and waste wood, plastic and other debris can be removed to facilitate the downstream process. If necessary, the raw materials can also be magnetically separated to remove scrap iron.

2) Material crushing. The raw materials are evenly fed into the primary crusher by the vibrating feeder, and the raw materials are crushed in the primary crusher. The materials with qualified particle size are transported by the conveying equipment to the fine crusher for further crushing, and the materials that do not meet the requirements are returned to the coarse crusher.

3) Sand making. The finely crushed stone can meet the feeding requirements of the vertical shaft impact crusher. At this time, the vertical shaft impact crusher is used to finely crush and shape the materials. The sand processed by the vertical shaft impact crusher has a uniform particle size.

4) Sand screening. Most sand screening processes use an inclined vibrating screen. According to user needs, the finished sand can be screened and classified into coarse sand, medium sand and fine sand.

5) Sand washing. In order to improve the quality of the finished sand, especially the cleanliness, special sand washing equipment can be configured to clean the sand after the sand making process.