- Features & Properties

- Technical Specification

- Gallery

- Related Products

1. Light weight, small size, especially suitable for working in narrow spaces;

2. Easy to transport, crawler walking without damaging the road, high adaptability;

3. Integration of multiple functions such as material receiving, crushing, and conveying;

4. Fully driven, capable of turning in place, especially suitable for narrow and complex sites;

5. Fuel-saving, the fuel saving rate can be as high as 25%;

6. A power unit can be attached to form an optimized design;

7. Good gradeability to meet complex engineering requirements.

Wheeled mobile crushing and screening plants

Wheeled mobile crushing and screening plants

PE Jaw crusher

PE Jaw crusher

Stationary crushing and screening plants

Stationary crushing and screening plants

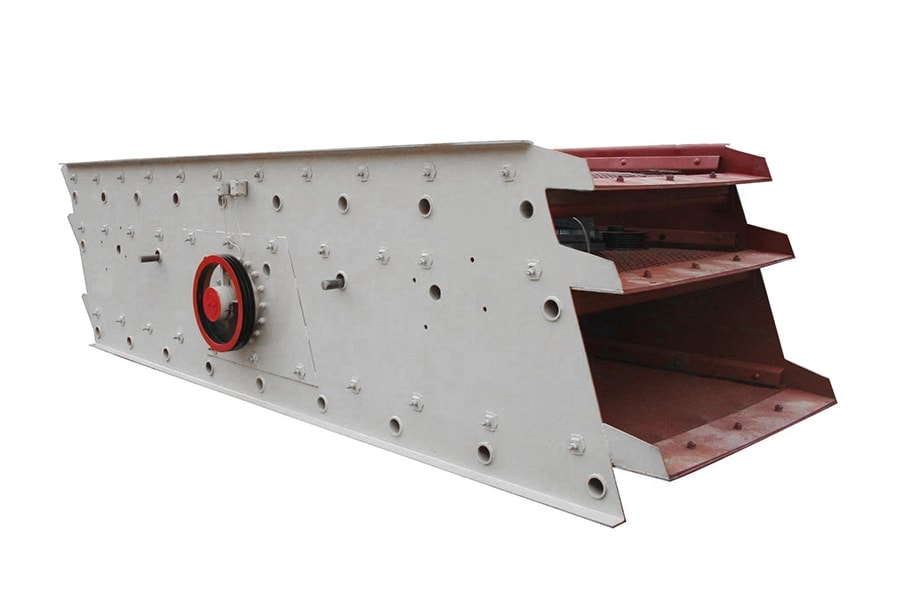

YK Vibrating screen

YK Vibrating screen

FAQ

Q: What are the similarities and differences between tire-type (wheeled) mobile crushing and screening plants and crawler-type (tracked) mobile crushing and screening plants?

A: Mobile crushing and screening plants are mainly divided into two types: tire type (wheeled) and crawler type (tracked). They eliminate many complex obstacles brought to crushing and screening by site, environment, foundation and logistics, so they are welcomed by more and more users. Next, I would like to analyze the characteristics and advantages of the two.

1) Similarities

1-1. Flexibility and time saving. The mobile plants can arrive directly at the work site and is not affected by changes in the site. It can start working after completing the position adjustment in a short time.

1-2. Integrated and complete unit. The mobile plants integrate material receiving, crushing, conveying and other functions. The reasonable and compact layout improves the flexibility of site deployment.

1-3. Transportation costs saving. The mobile plants can process materials on-site without having to move the materials away from the site, which greatly reduces the transportation cost of materials.

1-4. Flexible combination and versatile. The mobile plants can be combined according to the actual production requirements of the user, and can also work independently, giving them great flexibility.

2) Differences

2-1. Mobility ability. The tire-type (wheeled) mobile crushing and screening plant is actually a semi-mobile plant, because its transitional movement relies on the semi-trailer for traction. Therefore, in terms of mobility, it is not as good as the self-hydraulic driven crawler-type (tracked) mobile crushing and screening plant.

2-2. Applicable site. Since the tire-type (wheeled) mobile crushing and screening plant needs to be towed, it is more suitable for construction waste treatment, earthwork engineering, urban infrastructure and road construction and other industries. The crawler-type (tracked) mobile crushing and screening plant adopts a crawler fully rigid ship-shaped chassis, which has high strength, low grounding ratio, good passability, good adaptability to mountains and wetlands, and can even climb slopes, so it is mostly used in harsh environments such as some mines.

2-3. Work efficiency. When the tire-type (wheeled) mobile crushing and screening plant is working, the hydraulic legs under the frame are fixed, thus increasing the stability of the entire plant. Stability is the prerequisite for the operation of a mobile plant. Good stability enables the entire plant to be equipped with a large crusher. This means that the tire-type (wheeled) mobile crushing and screening plant can crush large materials with extremely high efficiency. The crawler-type (tracked) plant has weak stability, which limits its working efficiency.

2-4. Equipment performance. The tire-type (wheeled) mobile crushing and screening plant has a short wheelbase, a small turning radius, does not damage the road, and can travel flexibly on ordinary highways and work areas. The crawler-type (tracked) plant travels on crawler tracks, can be turned in place, and is equipped with wireless remote control as standard. It is easily driven onto a trailer and transported to the working site.

2-5. Crushed material quality. Currently, tire-type (wheeled) mobile crushing and screening plants are more commonly used in the crushing and processing of construction waste. The recycled aggregates produced by them have good particle size and are conducive to recycling. Because of its semi-open discharging system, it is suitable for crushing construction waste containing a small amount of steel bars. There is less over-crushing, and the particles are well formed. It is especially suitable for the production of recycled and environmentally friendly concrete bricks.

In summary, tire-type (wheeled) and crawler-type (tracked) mobile crushing and screening plants have their own characteristics, and the specific selection should be based on the user's requirements.